Technology is making roadway pavement management easier and more cost-effective than ever before. Find out how it could benefit your community.

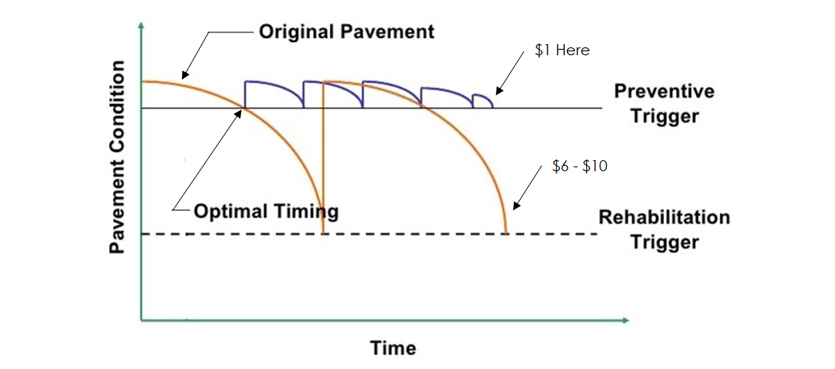

Many municipalities take a reactive approach to pavement maintenance on their local roads. Faced with a tight budget, they wait until a roadway deteriorates to the point it brings complaints from local drivers before they rehabilitate it. Ironically, their efforts to save money often wind up costing them much more in the long run. Research shows that every $1 invested now in preventative maintenance saves $4 to $10 in rehabilitation/reconstruction costs later.

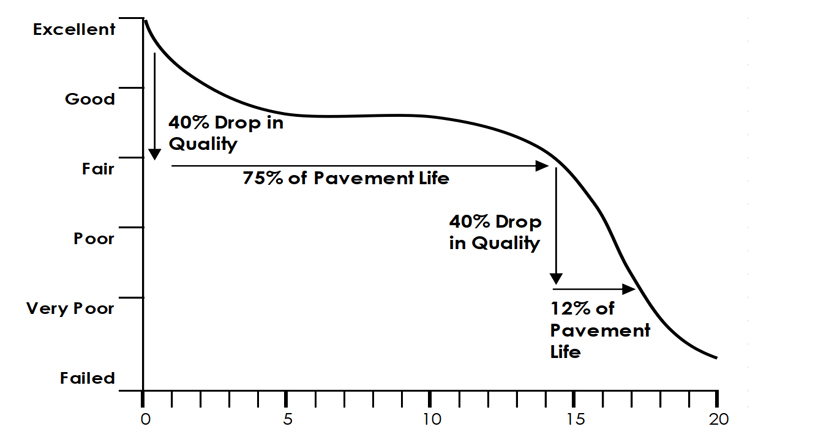

Pavement deteriorates at a fairly predictable rate. As the graph below shows, deterioration is slow for the first three-quarters of its life cycle. Then, in the final quarter, the deterioration accelerates rapidly.

Once it reaches critical condition, the pavement must undergo expensive reconstruction. Delaying the need for reconstruction saves a municipality significantly. This can be accomplished through a roadway pavement management program that involves regular application of inexpensive preventative maintenance techniques like crack sealing. As you can see in the graph below, waiting to address pavement until it hits the rehabilitation trigger costs significantly more over a period of time than investing in affordable preventative maintenance at regular intervals.

Clearly, a roadway pavement management program can be a wise investment for most municipalities.

What does a roadway pavement management program involve?

A roadway pavement management program involves collecting data, analyzing that data to determine maintenance and repair priorities, and implementing the plan.

In the past, these programs were labor-intensive. Public works personnel had to manually walk the streets of their community, logging signs of distress. Labor costs made this prohibitively expensive for many communities; it also was highly subjective. Two crew members might judge the same pavement differently on a day-to-day basis.

In a modern roadway pavement management program, Laser Crack Measurement systems (LCM) deliver consistent data faster and with more accuracy than was ever possible before. They use HD cameras and ground-based LiDAR laser scanning to collect more data than personnel can collect manually – and in much less time. These systems record precise coordination locations for each sign of distress, so that this information can be mapped and integrated into a municipality’s GIS. Photos and data on roadway signs, manholes, guiderail and other street level assets can be recorded and downloaded into the GIS, too.

A software program like MicroPaver then processes the data and gives each roadway section an objective score, indicating structural integrity, roughness, and safety condition. Objectivity is important. Thousands of dollars will be invested in maintenance and rehabilitation; it will be easier to get the consensus of your constituents on how that money is spent if the decision is backed up by scientific fact.

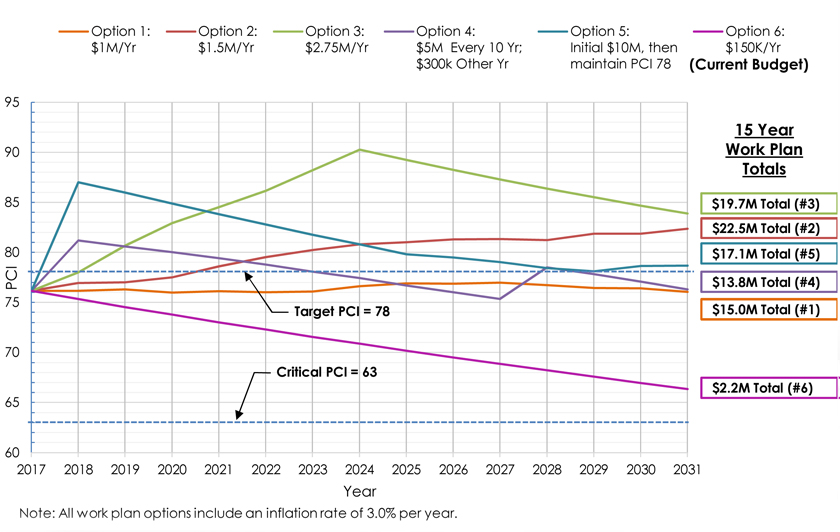

Once MicroPaver has given each roadway an objective rating of its condition, it can determine what effort is required to maintain that roadway at a satisfactory level. It can provide a range of options for pavement treatment, each one accompanied by a cost estimate. Municipal officials can see a graph of how the pavement condition would change over time, depending on which option they choose (as shown below).

At this point, the municipality will need to determine an annual roadway maintenance budget or target condition rating for the roadway network. This information will be used to finalize the actual work plan. The software will evaluate the cost and performance of various preservation and rehabilitation techniques and choose the optimum approach based on existing condition, degradation rates, budget, and desired roadway condition.

Once implemented, these recommendations should be evaluated and revisited – preferably every 5 years. The longer the program continues, the better results it will produce, as data is fine-tuned and lessons are learned.

How can your municipality benefit from a modern roadway pavement management program?

It can save you money.

As stated above, every $1 invested in preventative roadway maintenance saves $4-10 in rehabilitation or reconstruction costs later. A modern program using technology like the Laser Crack Measurement system and MicroPAVER software makes data collection and analysis less costly and labor-intensive than the manual methods of the past.

The data is more objective, consistent, and reliable.

Two crew members who are manually logging pavement distress could evaluate the same section of roadway differently, but Laser Crack Measurement technology ensures the data is logged the same way, every place and every time. This allows for a true, objective comparison of all roadway segments. Roadways selected for preventative maintenance are chosen because they have a demonstrated need, not because of an arbitrary timetable or guesswork.

It can help you achieve buy-in for budgetary expenditures.

Objective, factual data on the condition of the roadway is hard to ignore. Having this data can make it easier to get management buy-in on budgetary needs and achieve popular support for the pavement management program from the public.

It can help you win competitive grants.

Funding agencies make a big investment in projects when they award grants, and they are held accountable for those investments. They want to be sure they are putting their money behind projects that will make it to construction and be well-maintained over the long-term. Increasingly, funding agencies are requiring applicants to submit detailed data demonstrating the need for the project, plans and cost estimates that show exactly how the project will be successfully executed, and a plan to maintain the project once it’s complete. A modern roadway pavement management program can help local governments provide this data.

It integrates with your municipal GIS and provides powerful reporting.

Once the data is imported into your GIS, it can be applied to many other functions. This increases the return on your investment in data collection.

This screen shot from a municipal GIS shows pavement condition index (PCI) ratings for the local roadways. You can easily see at a glance which roads are in the most severe need of rehabilitation.

HRG can help your community implement a cost-effective approach to roadway pavement management like the one described here. Check out our article in the November 2018 issue of Pennsylvania Borough News magazine for even more about how these programs work. Contact us for a copy of the article.