Posts

5 Economic Benefits of Parks and Recreational Facilities

/in Insights-Landscape Architecture, Insights-Municipal, Insights-Planning, Insights-Recreation, Uncategorized /by Judy LincolnLISTEN: Bill Kick appears weekly on News Talk 103.7 Tri-State Economic Update

/in Uncategorized /by Judy LincolnStaub, Feath Discuss Demographic Shifts and Impact on Local Government

/in Company News, News-Municipal /by Judy Lincoln Our assistant vice presidents Tim Staub and Jim Feath are both featured in the March 2019 issue of Pennsylvania Township News magazine cover story, offering some insight on how municipalities can adjust policy and prepare for the needs of an aging population.

Our assistant vice presidents Tim Staub and Jim Feath are both featured in the March 2019 issue of Pennsylvania Township News magazine cover story, offering some insight on how municipalities can adjust policy and prepare for the needs of an aging population.

According to the article, 235 township residents in Pennsylvania turn 65 every day, and older adults are projected to outnumber adults for the first time time in U.S. history by 2035.

“Just how well-positioned is your community to allow them to age in place?” Tim asks.

He offers a number of ideas for making sure your township can retain residents as they age:

- promoting walkability with sidewalks and connections between neighborhoods and amenities

- incorporating universal design elements into construction standards that help residents stay in their home

- permitting multi-generational living arrangements such as shared housing and accessory dwelling units

The key, he says, is to make your zoning and construction codes flexible enough to accommodate the changing needs of your community.

Jim Feath discusses how to provide recreational facilities that meet seniors’ needs, but he also recommends analyzing local population trends before making any significant changes. Some municipalities are seeing an influx of young families. Township officials will want to provide facilities that meet the need of their individual community, not just chase trends. (HRG can help and often provides this service as part of a larger comprehensive plan or comprehensive recreation plan. Two of our clients — Cranberry Township and Dover Township — are also featured in the article, sharing the ways they proactively plan for their communities’ evolving needs.)

5 Reasons You Should Consider a Roadway Pavement Management Program

/in Insights-Local Government, Insights-Municipal, Insights-Transportation, Uncategorized /by Judy LincolnMinimizing the Cost of Connecting Homes with On-Lot Disposal Systems to Public Treatment

/in Insights-Water & Wastewater /by Judy LincolnClean water is essential to life, and life is priceless. But sometimes the cost of clean water can be too high for a community to bear. When it is, a mix of grants and forward-thinking design can make the cost more manageable as it did for the residents of a small village in Central Pennsylvania recently.

Kelly Township is a rural municipality in Union County, Pennsylvania, with a population of approximately 5,000 people. The Village of Kelly Crossroads is located in a remote area of the township and consists of 47 homes along Crossroads Drive, SR 1004, and Fort Titzell Road, SR 1003. These homes had historically used on-lot disposal systems for their sewage.

An on-lot disposal system, commonly referred to as a septic system, is a 3-stage treatment process that happens on the site of the home, rather than at a community treatment plant. Sewage collects in a septic tank on-site, where solids and scum are separated from the water via settling and flotation. Pipes then carry the water to the soil where it is absorbed into the ground and purified in nature.

Unfortunately, these systems have a high rate of malfunction, and Kelly Crossroads was no exception. As part of an Act 537 Plan update in 2010, the township confirmed that almost half of the on-lot disposal systems in Kelly Crossroads were malfunctioning. Another 45% exhibited signs of suspected or potential malfunction. Only 6% of the on-lot disposal systems in Kelly Crossroads were functioning properly.

This map shows the location of all the on-lot disposal systems in Kelly Crossroads, and the colors indicate how well each system was functioning. As the map shows, some level of malfunction was widespread throughout the system.

To make matters worse, the township had good reason to believe that these malfunctions were contaminating residents’ water supply. A portion of the homes in Kelly Crossroads relied on wells for their water, and more than half of those wells tested positive for coliform bacteria, an indicator that human waste had come in contact with the water supply.

The township has an obligation to protect the public health, so it needed to address these malfunctioning on-lot disposal systems. Unfortunately, on-site repair was not an option for approximately 70% of the systems. HRG analyzed several alternative approaches and determined that the most cost-effective option was to retire the on-lot disposal systems and replace them with a low-pressure system connected to a package treatment plant.

Cost-effective does not mean low-cost, however. Connecting new homes to a public treatment system is always a costly endeavor, and the cost to connect Kelly Crossroads was estimated at more than $1.6 million. Each homeowner would have to cover the cost of connecting to the system and share in the cost of building the infrastructure it required. This would amount to several thousand dollars in fees per home, a significant burden for an area where the median household income is approximately $55,000.

HRG helped the township obtain nearly $1.5 million in funding from the U.S. Department of Agriculture, Rural Utilities Service, 75% of which was grant money. This funding has dramatically reduced the cost of sewer service to the community.

During initial planning phases of the project, user rates were projected to be as high as $200 per user each month. With the USDA funding, monthly user rates will be $69.

(Learn more about the USDA’s Rural Development Program here.)

HRG designed the system for future expansion of the user base in order to make the project more cost-effective. Capacity is available to connect an additional 5-10 homes if they are constructed adjacent to the system through extension of the LPS system only. Adequate space is also available for future expansion of the treatment plant facilities if more capacity becomes necessary. Planning for future needs now helps to minimize costs down the road.

Construction began in August 2017 and was completed in August 2018. Residents began utilizing the public system in June 2018.

A home in Kelly Crossroads with a recently installed grinder pump

Though the investment is significant, there is no better investment a community (or its residents) can make than in its own health and safety.

Municipalities like Kelly Township want to ensure their residents have clean water, but they are sensitive to how difficult monthly bills can be for residents to pay. They need an engineer who can deliver high quality infrastructure, while helping the community find ways to afford the improvements they need.

A firm with a dedicated team of financial experts can skillfully position the municipality for grants as HRG did for Kelly Township. At the same time, HRG’s water and wastewater professionals designed the system to accommodate future expansion in order to minimize costs moving forward.

Our wastewater treatment professionals are creative problem-solvers, and our financial specialists are experts in water and wastewater financing. We have extensive experience with programs like the USDA’s Rural Development Program, whose support is crucial to ensuring rural communities have quality water and sewer service.

SPECIFICATIONS:

- Low Pressure Collection & Conveyance System w/Homeowner-Owned Grinder Pumps

- 8,200 linear feet of 1.5” – 3” diameter LPS and appurtenances (cleanouts, air release valves, etc.)

- 13,500 GPD Package WWTP consisting of a pre-aeration anoxic activated sludge process and control building

The new 13,500 GPD package wastewater treatment plant serving the Kelly Crossroads community

Cumberland County Receives Safety Award for Craighead Bridge

/in Company News, News-Transportation /by Judy LincolnCumberland County has been recognized with a Road & Bridge Safety Award for the Craighead Bridge replacement project. The award is given jointly each year by the Pennsylvania Highway Information Association, County Commissioners Association of Pennsylvania, and PennDOT to the best road and bridge safety improvement projects undertaken by county governments across the state.

The county’s director of planning, Kirk Stoner, accepted the award on behalf of the commissioners at the County Commissioners Association of Pennsylvania Conference in Gettysburg yesterday.

(From left) Jason W. Wagner, Managing Director, Pennsylvania Highway Information Association; Brian D. Emberg, Sr. Vice President and Chief Technical Officer, Herbert Roland and Grubic, Inc.; Kirk Stoner, AICP, Director of Planning, Cumberland County; Fred Thompson, Vice President, Kinsley Construction; Phil Royer, Estimator/Project Manager, Kinsley Construction; James D. Ritzman, PennDOT Deputy Secretary for Planning; and County Commissioners Association of Pennsylvania President and Lancaster County Commissioner Dennis Stuckey.

Herbert, Rowland & Grubic, Inc. designed the replacement bridge for Cumberland County, which improves safety for local residents in several ways:

- The new bridge is stronger and replaces one with more than 100 years of wear and tear.

- The new bridge can safely carry two lanes of traffic, where the previous bridge could only carry one.

- Back-ups and rear-end collisions had occurred frequently at the original bridge and have been eliminated by the new bridge.

- The replacement bridge was built on a new alignment that gives drivers a better view of oncoming traffic.

- The new bridge has a flared intersection where Zion Road meets Old York Road. This makes it easier for drivers to turn onto and off of the bridge.

- The new bridge has no weight restrictions, and its improved sight distance and turning radii make it easier for emergency vehicles, school buses, and delivery trucks to reach local residents.

The original Craighead Bridge held a special place in the heart of the community and is even featured on the South Middleton Township seal. The county struck a deal with a non-profit organization to preserve the original bridge for bike and pedestrian use, so that future generations can continue to connect with this historic fixture along the Yellow Breeches creek. Local residents get the safety and convenience of a modern bridge while preserving the charm and memories of the original bridge.

Original Bridge

New Bridge

ABOUT CUMBERLAND COUNTY

Cumberland County is the fastest growing county in the Commonwealth and offers the perfect mix of small town,

suburban and rural living. Established in 1750, Cumberland County consistently maintains one of the lowest tax

and unemployment rates in the State, while providing exceptional services for its more than 250,000 residents. More

information on Cumberland County can be found at www.ccpa.net

ABOUT HRG

HRG is a nationally ranked Top 500 Design Firm, providing civil engineering, surveying and environmental services to public and private sector clients. The 200-person employee-owned firm currently has office locations in Pennsylvania, Ohio, and West Virginia. For more information, please visit the website at www.hrg-inc.com.

Porous Pavement in Parking Lot Helps Township Meet MS4 Requirements

/in Insights-Municipal, Insights-Water Resources /by Judy LincolnIt’s National Water Quality Month, and we’re sharing projects we’ve designed that help improve water quality in the communities we serve. Today, we’re profiling the West Caracas Avenue parking lot in Derry Township.

This 40,000 square foot parking lot includes 11,500 square feet of porous asphalt, which reduces the volume of stormwater runoff, prevents pollutants from entering the watershed, and promotes groundwater recharge.

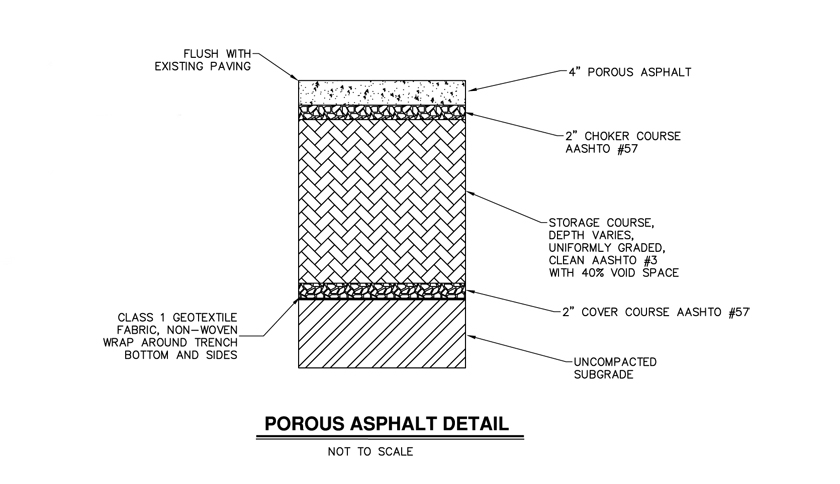

What is porous pavement?

Porous pavement (a.k.a. pervious pavement) comes in many forms: concrete, asphalt, paver blocks, reinforced turf, recycled glass, and more. Traditional asphalt and concrete is densely packed with fine materials, but porous pavement uses coarser materials and a higher percentage of air voids in between these materials. A clean stone bed consisting of 1 inch to 3 inch stone with a high void ratio is installed below the porous surface to provide temporary runoff storage and allow for infiltration.

The space in between the coarser material provides a place for water to seep through to the soil underneath.

What are the advantages of porous pavement?

It can trap solids and pollutants that otherwise would’ve been carried to lakes and streams by stormwater collected in inlets. These pollutants seep through the pavement into a bed of rocks below, where they undergo the natural cleansing process that has purified our stormwater for hundreds of years before asphalt and concrete were invented.

It reduces stormwater runoff, thereby reducing the need for stormwater detention basins and stormwater infrastructure. Porous pavement allows the rain water to infiltrate the ground; therefore, it reduces the volume of stormwater runoff. This can reduce the number of inlets and storm pipes a client needs to be build (and reduce construction cost associated with that infrastructure).

See water infiltrate the porous pavement parking stalls almost immediately, while water collects on the conventional pavement outside the stall.

It can reduce flooding risks. Heavy rains can be absorbed into the ground instead of overloading inlets and detention basins.

It recharges the groundwater. Rain is absorbed back into the water supply, rather than being collected, stored and released from a detention basin.

It reduces the heat island effect of paved surfaces because air can circulate better through this material.

It reduces winter maintenance since the stone bed below the porous pavement tends to absorb and retain heat allowing snow to melt faster. So typically light snow and ice accumulation are handled with little to no maintenance.

What should you consider before investing in porous pavement?

It is coarser than traditional paving materials, but it is still fine enough to meet ADA standards and most people cannot tell the difference in appearance.

It must be carefully designed by engineers to work properly. The designer needs to know how quickly the soil beneath the pavement can absorb water (some soils absorb more quickly than others) and design the paving surface and stone bed accordingly. Otherwise, water can build up underneath the surface and can cause damage or surface flooding. Also, porous pavement is ideally suited for flatter surfaces to promote stormwater absorption and minimize the stone bed depth. On steeper surfaces benching or terracing of the stone bed is needed to maintain a reasonable stone bed depth and minimize excavation.

Maintenance requirements are different than they are for traditional pavement, depending on the material chosen. Certain materials require frequent vacuuming to prevent the voids or “pores” from being clogged. Sand or cinders should not be applied on or adjacent to porous pavement. More advanced materials – like elastomerically bound glass – have reduced maintenance needs.

Its strength rating is lower than traditional paving materials due to the increased air content. Therefore, it is not recommended for surfaces that will see heavy volumes of traffic or loading areas that will be frequented by large trucks. However, as the popularity of porous pavement continues to grow, many paving companies are developing higher strength materials.

What are the best uses for porous pavement?

Due to the lower strength of porous paving materials, it is best used for low-volume applications like:

- Parking spaces

- Residential alleys/roads

- Residential driveways

- Sidewalks and Walking paths

- Tennis Courts

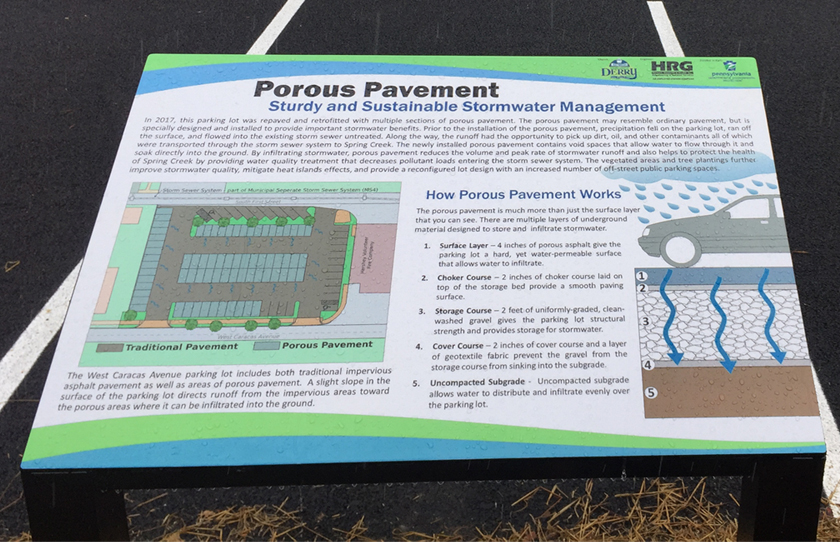

Derry Township chose to pursue porous pavement in the West Caracas Avenue parking lot to meet the requirements of its MS4 stormwater management program and reduce the possibility of flooding. The porous pavement and vegetative islands in the lot are designed to completely infiltrate the runoff from a 100-year storm event and reduce the amount of sediment, nitrogen and phosphorous entering the watershed. This helps the township meet its Chesapeake Bay pollutant reduction plan goals.

Informational signage educates the public about the various Best Management Practices (BMPs) used in the lot and the benefits of infiltration to water quality. This helps the township meets the MCM #1 (public education) goal of its MS4 permit.

DEP awarded the township a $200,000 Local Stormwater BMP Implementation Grant, which covered almost half of the project cost.

But the new parking lot provides other benefits to the community besides improved water quality. It also accommodates more cars and has better access from local streets, too. This is important because it’s located in a busy section of downtown Hershey, where it serves visitors to the local restaurants, the Hershey Story museum, the Hershey Theater, and many local shops. It also accommodates Life on Chocolate events in ChocolateTown Square.

The West Caracas Avenue parking lot project shows that development and environmental benefits can peacefully coexist and be affordable for communities at the same time. Municipalities don’t have to choose between protecting water quality and promoting economic development; they just have to invest wisely.

Reduce the Cost of MS4 Compliance and Pollutant Reduction Plans Through Cooperation

/in Insights-Local Government, Insights-Municipal, Insights-Water Resources, Uncategorized /by Judy Lincoln

Stormwater management has become a major priority for environmental agencies over the past decade, and communities are struggling to meet the increasing requirements to reduce stormwater pollutants and runoff volume. The cost is simply too high for many municipalities to bear alone, but it becomes much more manageable if municipalities can share the burden with their neighbors.

Take the Pollutant Reduction Plan requirement of the MS4 application as an example. If a municipality submits a Pollutant Reduction Plan on its own, it is limited to constructing BMPs within its own borders or the drainage way of its impaired streams, but DEP will generally accept the construction of BMPs anywhere within the watershed for an MS4 permit that is submitted by a regional cooperative. This means cooperating municipalities can install BMPs that yield the greatest pollutant load reduction for the lowest cost.

Usually the largest expense associated with BMP construction is the cost of acquiring land on which to build the BMP. An individual municipality may not have much land on which to build, particularly if it is an urban municipality in which most of the available land has already been developed. As a result, the municipality may be forced to implement a large number of BMPs that each provide only marginal individual benefit in order to meet the pollutant reduction goal. If a municipality submits a regional plan with other communities in the same watershed, it will have access to a much greater land area on which to build BMPs and a reduced need for right-of-way acquisition and easements. This allows the participating municipalities to build the most effective water quality measures in the places with the greatest need.

Any improvements in upstream water quality will lead to improvements in downstream water quality, so a municipality can still see improvements in its water quality using a watershed-based approach even if a particular BMP is not located within that municipality’s borders.

When BMPs are constructed on a watershed-wide basis, the construction cost is typically lower due to economies of scale, and the water quality results are better.

Herbert, Rowland & Grubic, Inc. (HRG) is working with the Wyoming Valley Sanitary Authority on a regional stormwater collaboration that includes 32 municipalities in Luzerne County. These municipalities intend to meet 70% of their sediment reduction goal with a single BMP: conversion of existing flood control levees into a constructed wetland with a sediment forebay and a meandering stream channel.

Regional cooperation can save municipalities money in other ways besides BMP construction. For example, the cost of preparing the Pollutant Reduction Plan itself will be much lower as a result of cooperation due to economies of scale.

Hiring a consultant to assist with pollutant reduction planning can cost thousands of dollars. If that cost is shared with 10 other municipalities, each individual municipality only has to pay a small portion.

It’s like sharing your first apartment with two roommates when you were in your 20s. The fixed cost of rent and utilities is the same whether one person lives there or three, but each person pays less if they can split that cost three ways (instead of renting their own individual apartments).

Stormwater management involves many fixed costs like the cost of owning equipment to clean out inlets or conduct outfall inspections.

Spreading those costs across a greater number of users means each user pays a smaller price for service.

Another way cooperation can reduce the cost of stormwater management is by giving municipalities increased purchasing power. Generally, you can negotiate lower unit costs for items when you buy them in larger quantities. For example, cooperating municipalities could replace or slip line several miles of pipe for a lower cost if the work was completed as part of a larger, regional project. These savings apply to the bidding of services, too. The municipalities working with the Wyoming Valley Sanitary Authority saved hundreds of thousands of dollars on base mapping (i.e. orthophotography, impervious area, etc.) by participating with WVSA under a single project (rather than having each municipality bid its own contract).

Municipalities have greater purchasing power when they cooperate on stormwater management solutions. For example, cooperating municipalities could slip line several miles of pipe for a lower cost if the work was completed as part of a larger, regional project.

A regional cooperative also has more borrowing power than a single municipality, and funding agencies are more likely to award a grant or loan to a regional project than one submitted by a single municipality. Funding agencies prefer regional projects because they believe regional cooperation streamlines costs, and politicians tend to support projects that benefit as large a constituent base as possible. A regional initiative should be tied together by legal agreements that assure the funding agency all funding will be properly administered. (These legal agreements are also required to meet DEP requirements for submission of a regional pollution reduction plan.)

This post is an excerpt from a longer article in the July-August-September issue of Keystone Water Quality Manager magazine. The article is focused on the cost savings communities enjoy by cooperating with regional partners on their stormwater management programs. Read the magazine for advice on finding partners for your stormwater management program or contact us to request a copy.

Erin G. Letavic, P.E., is the regional manager of civil engineering services in HRG’s Harrisburg office. She guides municipalities and cooperative groups throughout Pennsylvania through the management of their MS4 permits, provides grant application development and administration services, and provides retained engineering services to local government.

Adrienne Vicari, P.E. is the financial services practice area leader at Herbert, Rowland & Grubic, Inc. (HRG). She provides strategic financial planning and grant administration services to numerous municipal and municipal authority clients. She also serves as project manager for several projects involving the creation of stormwater authorities or the addition of stormwater to the charter of existing authorities throughout Pennsylvania.

Polymer Concrete Manholes Offer Longer Life and Less Disruptive Construction Process for Sewer Systems with Different Needs

/in Insights-Water & Wastewater /by Judy LincolnRegularly replacing deteriorated concrete manholes is an expense (and inconvenience) that most sewer systems have learned to live with, but what if they didn’t have to?

We recently incorporated polymer concrete manholes into the design for two of our clients and wanted to share the benefits of this technology with other clients who might be considering manhole repair projects in the near future.

The West Goshen Sewer Authority wanted a long-term structural solution to the hydrogen-sulfide-based Microbial Induced Corrosion (MIC) in its system. We designed 60-inch polymer concrete manholes to replace the severely deteriorated, precast concrete manholes they had on a 30-inch interceptor because polymer concrete is known for its corrosion resistance and 50-year life expectancy.

The Lower Swatara Township Municipal Authority wanted to rehabilitate a 48-inch, precast concrete manhole downstream of a force main discharge. Like West Goshen’s manholes, this one was also severely deteriorated due to hydrogen-sulfide-based Microbial Induced Corrosion. Therefore, the corrosion-resistant properties of polymer concrete seemed like a natural solution, but the polymer provided an additional advantage: Its superior strength allows for thinner walls. Lower Swatara’s manhole was located between a state road and a land development project that would be changing the finished grade at the manhole. They needed to rehabilitate the manhole to a new finished grade while minimizing bypass pumping across the state road. The new polymer concrete manhole insert was sized to fit inside the existing manhole, and bypass pumping was unnecessary.

Polymer concrete has existed for several decades, but, for most of that time, it was too expensive for sewer systems to use. Technology has advanced, and the price has come down significantly. Leading edge systems are considering its benefits more and more. Chief among those benefits is corrosion resistance.

Wastewater contains bacteria that naturally produce hydrogen sulfide gas (H2S). This gas leads to Microbial Induced Corrosion (MIC), which eats away at conventional concrete.

To prevent this, sewer systems traditionally use sulfate-resistant Portland cement, which can provide moderate resistance against MIC. In severe situations, sewer systems use concrete additives, coat the concrete, or line it with PVC or HDPE. Polymer concrete provides sewer systems with another option to prevent damage where high levels of H2S-based MIC is present.

A badly corroded manhole

Many manufacturers produce polymer concrete for sewer system applications. Some use steel reinforcement, while others use fiberglass rebar. Some provide a 50-year warranty for their manholes.

But polymer concrete can be used for more than manholes; it can also be used for pipes and other structures (such as wet wells), too.

An engineer can help you evaluate whether polymer concrete is the right choice for your sewer system and what type will perform best for your particular needs.

Call us to discuss the condition of your sewer system and whether polymer concrete could benefit you.

Matthew Cichy, P.E., is a senior project manager in HRG’s water and wastewater group. He is an expert in sewer system design, construction, and long-term asset management. His experience includes water distribution systems, wastewater collection and conveyance systems, pumping stations, and water and wastewater treatment plants.

Matthew Cichy, P.E., is a senior project manager in HRG’s water and wastewater group. He is an expert in sewer system design, construction, and long-term asset management. His experience includes water distribution systems, wastewater collection and conveyance systems, pumping stations, and water and wastewater treatment plants.

Learn more about our work with the Wyoming Valley Sanitary Authority in this 3-part series published in The Authority, a magazine published by the Pennsylvania Municipal Authorities Association.

Learn more about our work with the Wyoming Valley Sanitary Authority in this 3-part series published in The Authority, a magazine published by the Pennsylvania Municipal Authorities Association.